Simple mod from last Saturday night (I really need to get out more!).

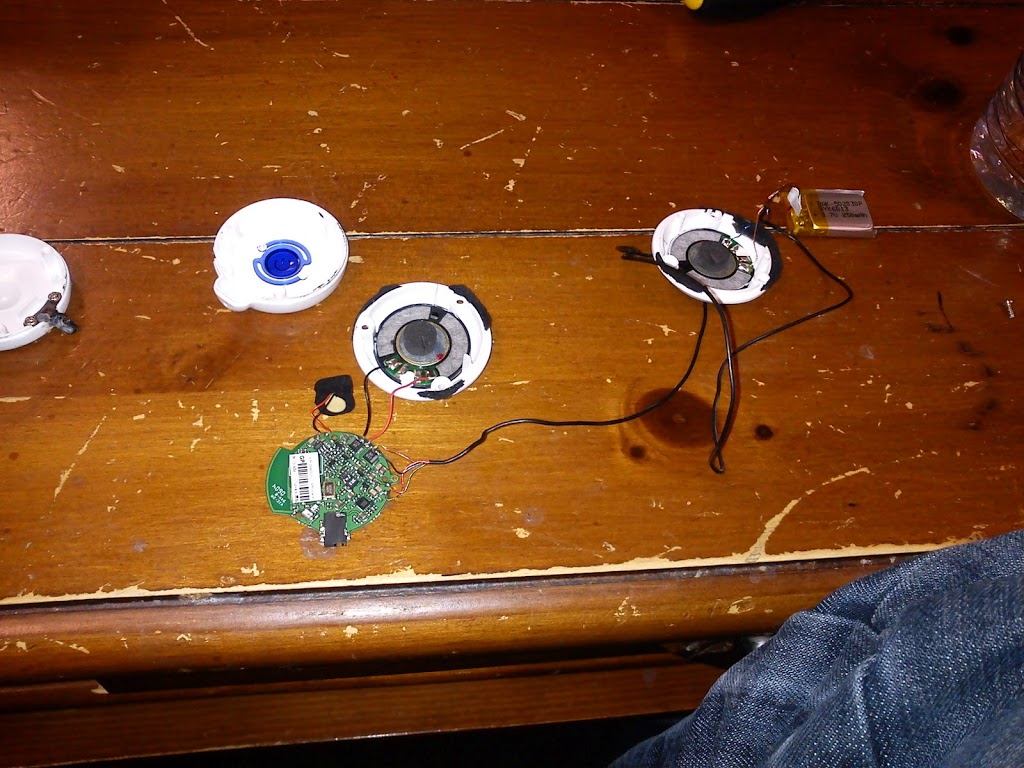

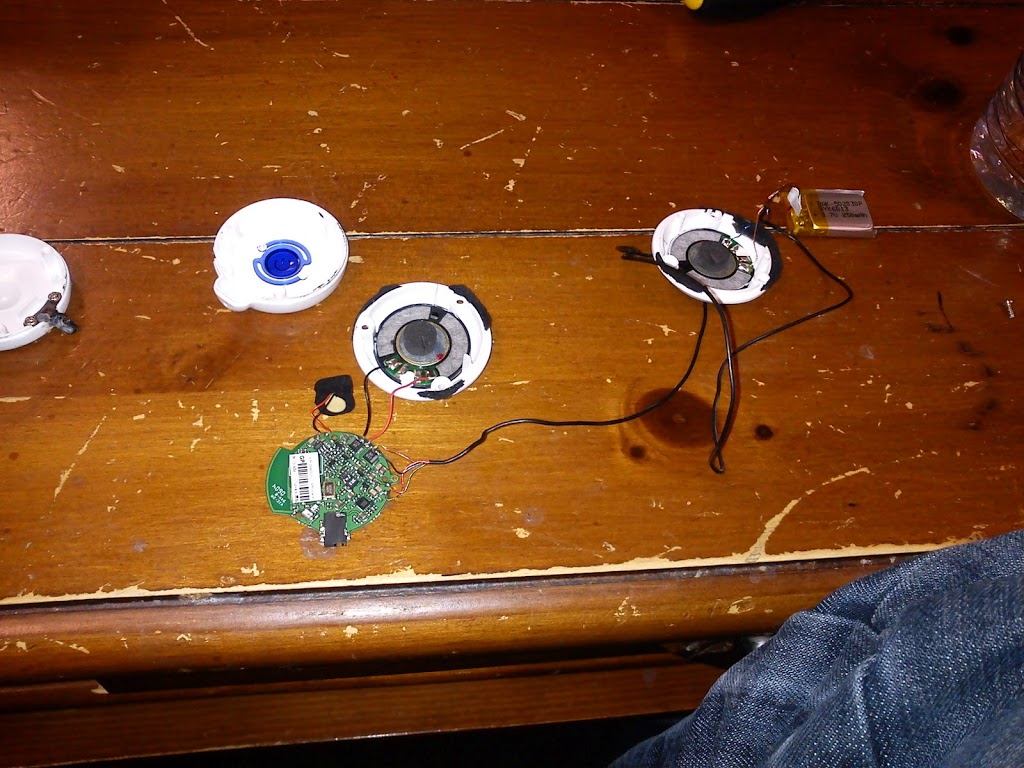

I have a pair of bluetooth headphones but unfortunately the headband is broken and one of the speakers is a bit dodgy so I decided to mod it to have a 3.5mm socket.

When I got them open I found that the battery was in the left ear and the main-board in the right. After tracing the cables it was a simple job to move the battery to the main unit. You may notice the mic on the right of the pic below, basically I forgot about it as I do not need it – oops.

Pretty much everything on the board is surface mount but luckily the headphone wires and through hole. Even so the holes were tiny and plated so removing the old solder was a nightmare, in the end heating up the wire and pushing it through. I the soldered on a set of wires for connecting to the socket scavenged from an old soundcard.

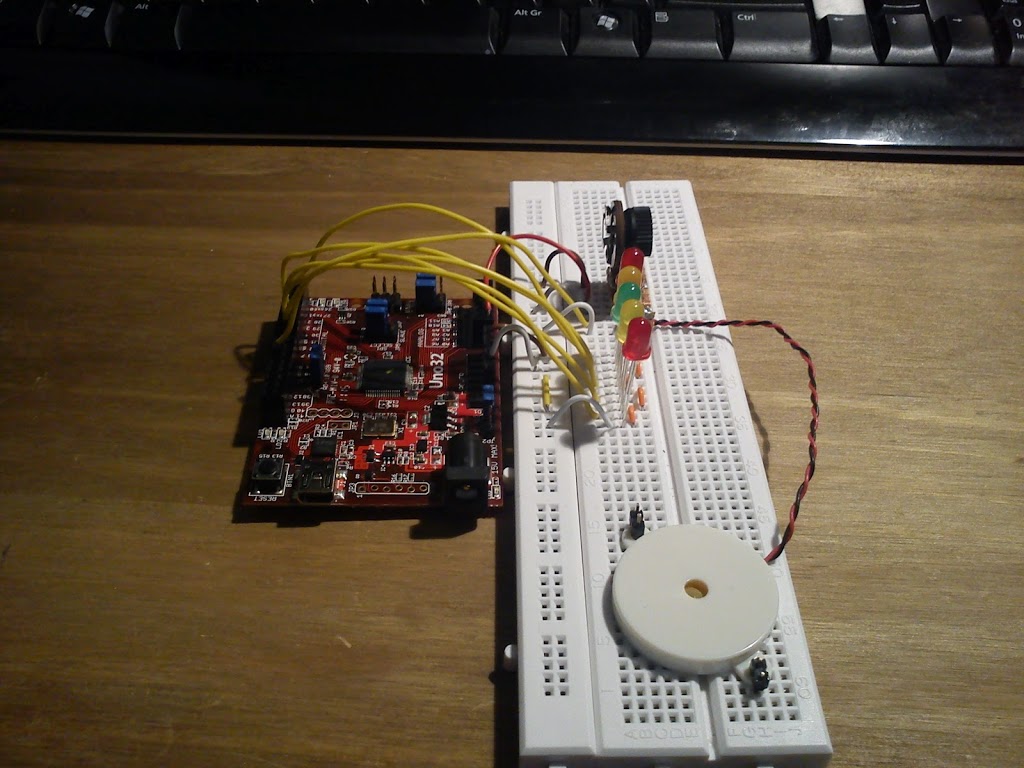

Not the most delicate job I have ever done but never mind! I then ran everything through a breadboard to get the wiring right and test everything.

After soldering on the socket I then knocked up a quick case laser cut from 3mm acrylic.

The buttons were nice and simple as they were surface mount push buttons so I just cut some button shape hole and stuck the middles of the cut outs back in on top of the buttons.

Although not the most refined design ever it works pretty well and opens the device up to a lot more applications than previously. I may re-design the case at some point as it doesn’t fit perfectly but for now it will do!

We are still waiting for the test tubes to arrive for the Axolotl sensor after finding some of the right size and will put a full post up when its complete.

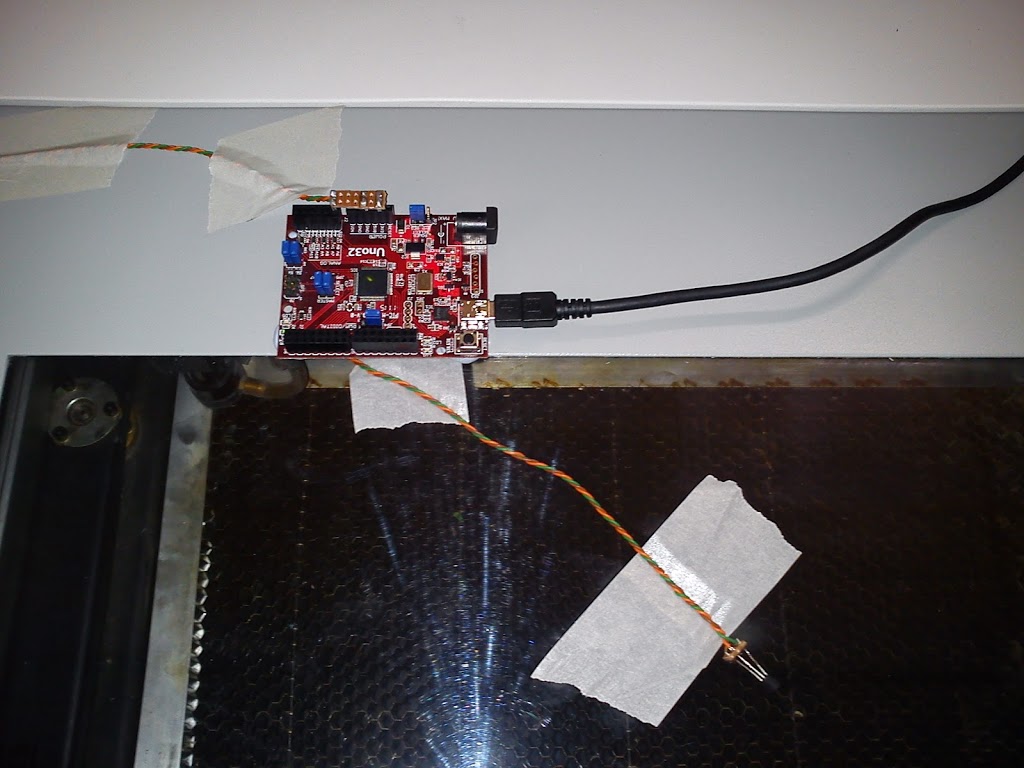

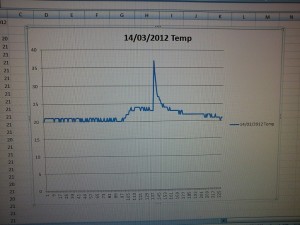

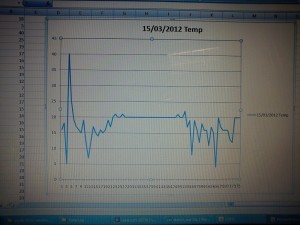

The problem with the interference and the laser temp sensor has proved impossible to re create anywhere else! We will work on that one.