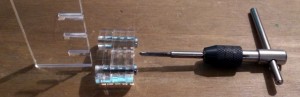

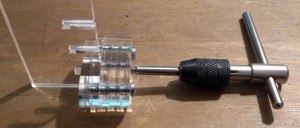

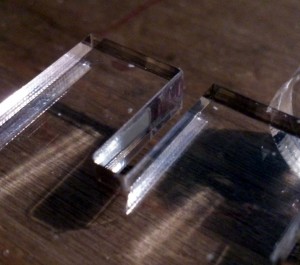

Gary the gecko gets a bit funny about his environment so we have to keep an eye on his temperature and humidity. We could have gone a purchased one but that would have been too easy! One ATMega328, home brewed PCB, LCD screen, DHT11 sensor and a laser cut case and we are away!

Not many notes on this one as the PCB creation was experimental and I will be writing it up fully later.

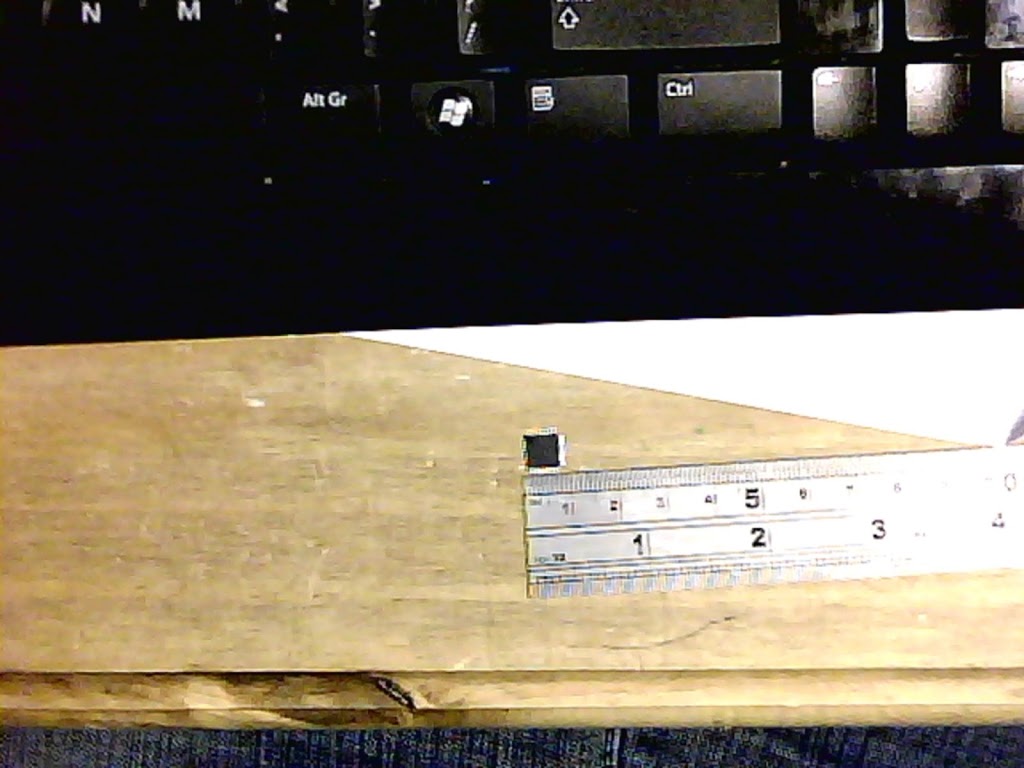

Anyway, here are some pictures.

More pics:

The button is so it doesn’t burn power with the backlight

Like this

Sensor in an old mic housing.

Gary

Gary

Code if you want it, un-tidied and barely changed from

Adafruits code. You will want the library on the tutorial as well.

**************************************************

// Example testing sketch for various DHT humidity/temperature sensors

// Written by ladyada, public domain

#include “DHT.h”

#define DHTPIN 13 // what pin we’re connected to

#include <LiquidCrystal.h>

LiquidCrystal lcd(5,6,7,8,9,10);

#define DHTTYPE DHT11 // DHT 11

// Connect pin 1 (on the left) of the sensor to +5V

// Connect pin 2 of the sensor to whatever your DHTPIN is

// Connect pin 4 (on the right) of the sensor to GROUND

// Connect a 10K resistor from pin 2 (data) to pin 1 (power) of the sensor

DHT dht(DHTPIN, DHTTYPE);

void setup() {

lcd.begin(16, 2);

lcd.clear();

Serial.begin(9600);

Serial.println(“DHTxx test!”);

lcd.print(“Starting…”);

dht.begin();

delay(500);

}

void loop() {

// Reading temperature or humidity takes about 250 milliseconds!

// Sensor readings may also be up to 2 seconds ‘old’ (its a very slow sensor)

int h = dht.readHumidity();

int t = dht.readTemperature();

// check if returns are valid, if they are NaN (not a number) then something went wrong!

if (isnan(t) || isnan(h)) {

Serial.println(“Failed to read from DHT”);

}

else {

Serial.print(“Humidity: “);

Serial.print(h);

Serial.print(” %t”);

Serial.print(“Temperature: “);

Serial.print(t);

Serial.println(” *C”);

}

//LCD Display

lcd.clear();

lcd.setCursor(0, 0);

lcd.print(“Temp : “);

lcd.setCursor(11, 0);

lcd.print(t);

lcd.setCursor(13, 0);

lcd.print(“c”);

lcd.setCursor(0, 1);

lcd.print(“Humidity: “);

lcd.setCursor(11, 1);

lcd.print(h);

lcd.setCursor(13, 1);

lcd.print(“%”);

delay(1000);

}

*****************************************