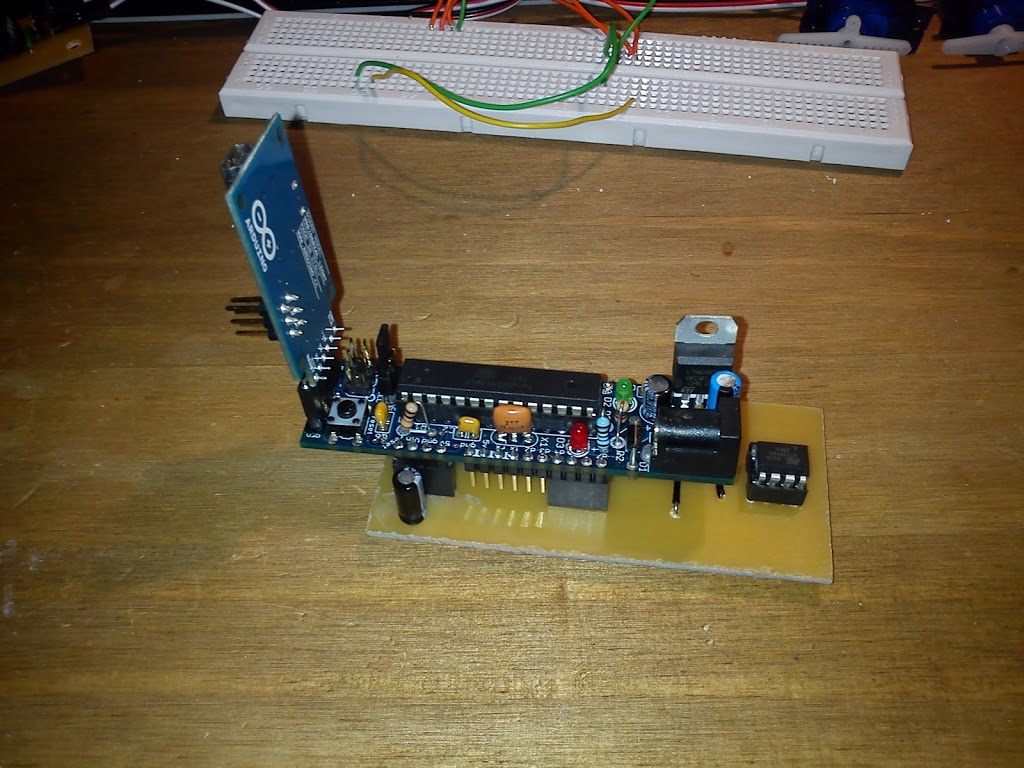

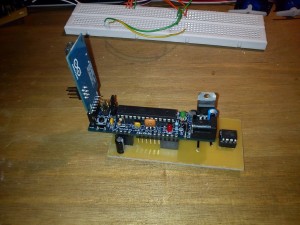

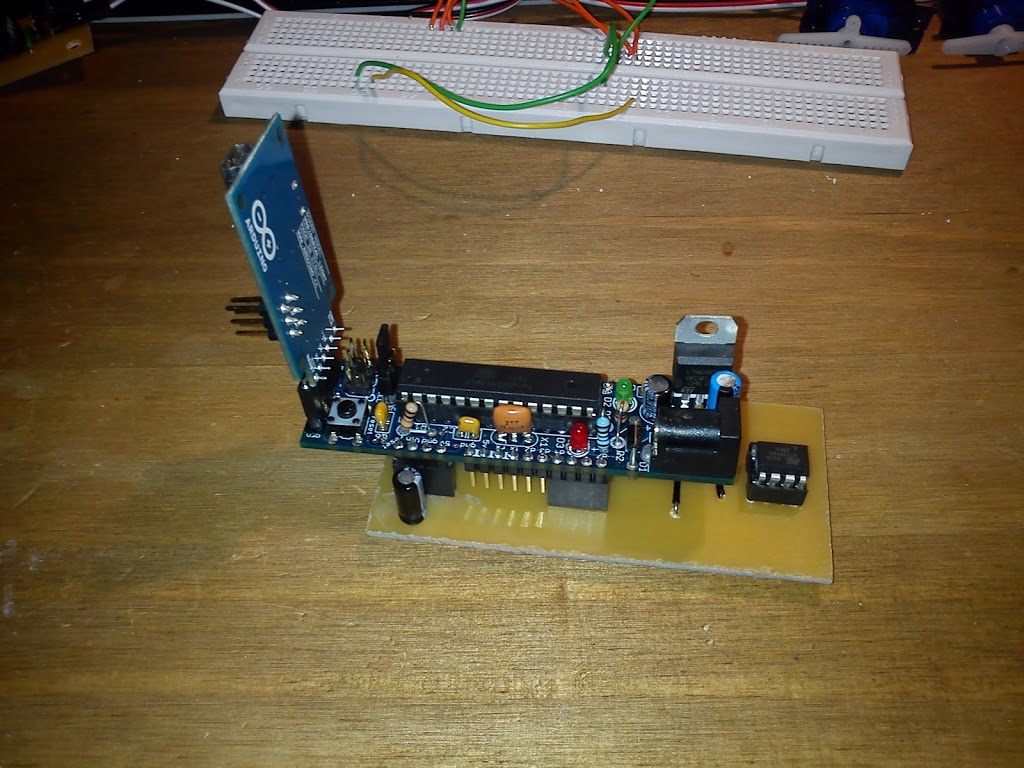

We have been doing a lot of ATTiny programming recently and decided to simplify the process by making a board to plug everything in to rather than breadboarding it every time.

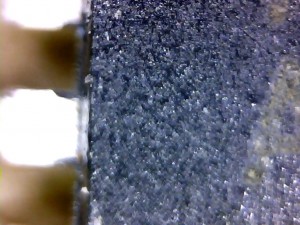

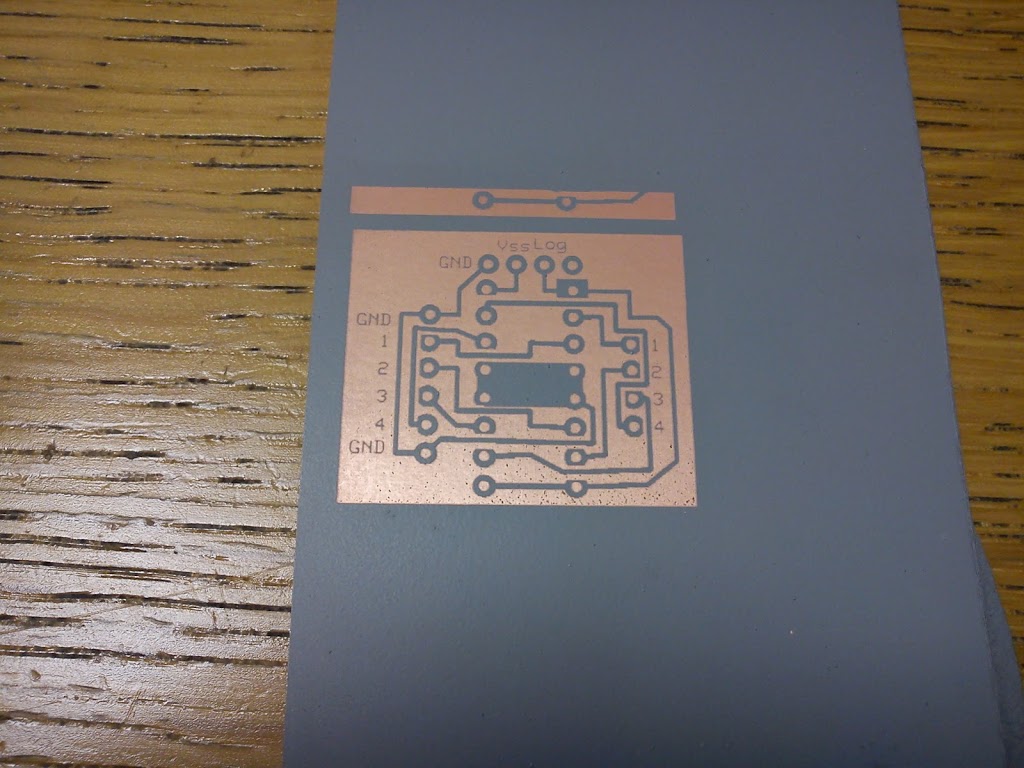

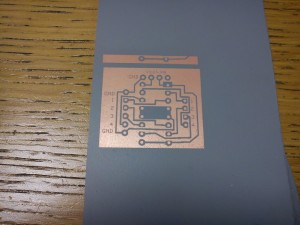

Rather than perf board we decided to make up a Laser masked PCB board to take a boarduino, ATTiny and reset overide capacitor. More after the break:

A comprehensive overview of the setup can be found here http://hlt.media.mit.edu/?p=1695.

We did have a couple of problems getting everything to compile and had to manually install winavr, modify our ATTiny libraries and modify softwareserial. Most of this is due to using windows and upgrading from arduino versions 0023 to 1.0 half way through a project! oops.

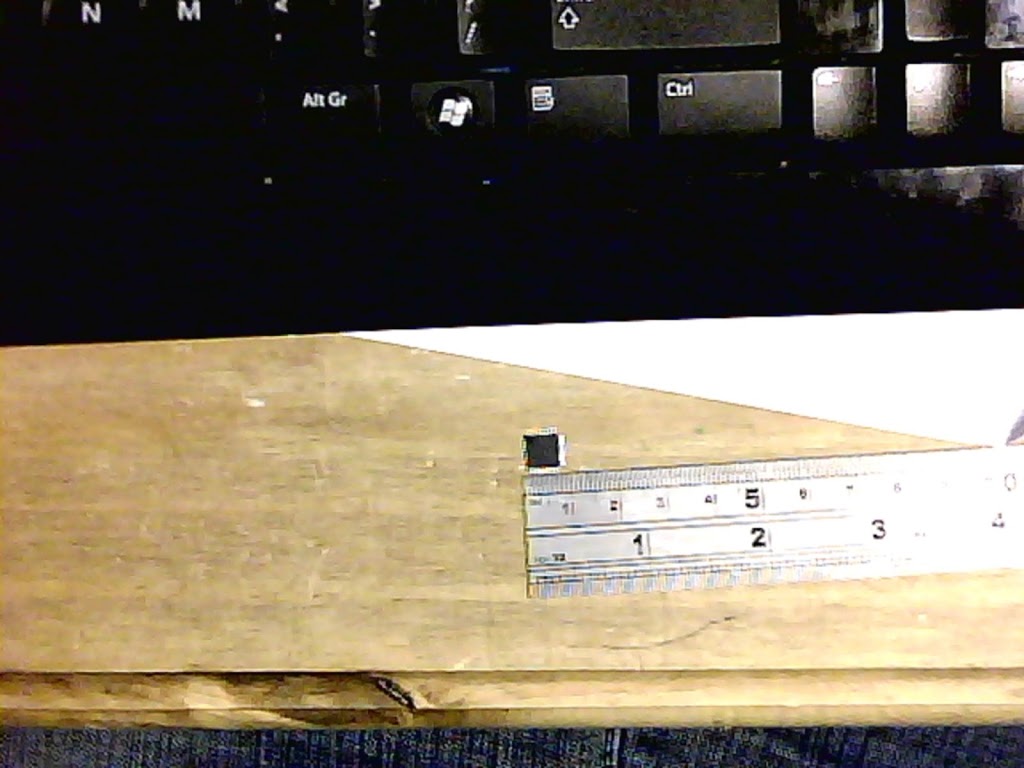

The new setup is much more a plug and play solution rather than trying to set up a breadboard each time and we minimised the copper removed from the board which will save our etchant and looks nicer on the board!

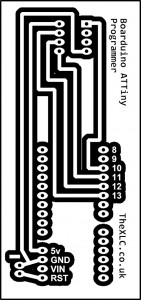

Below is the board graphic as a bitmap for running through the laser. This is different to the board above in that it actually works, unlike version 1!

EDIT: I have discovered that Arduino 1.0 will not programme the ArduinoISP sketch correctly onto the boarduino. I have to load this using Arduino 0022 or 0023. I can then use 1.0 to programme the AtTiny – Chris.