After I re-wired Braunston Ltd’s vinyl cutter for the 5th time they finally admitted defeat and purchased a new one from CTR Lasers. This meant that I was free to mess around with the scrapped one.

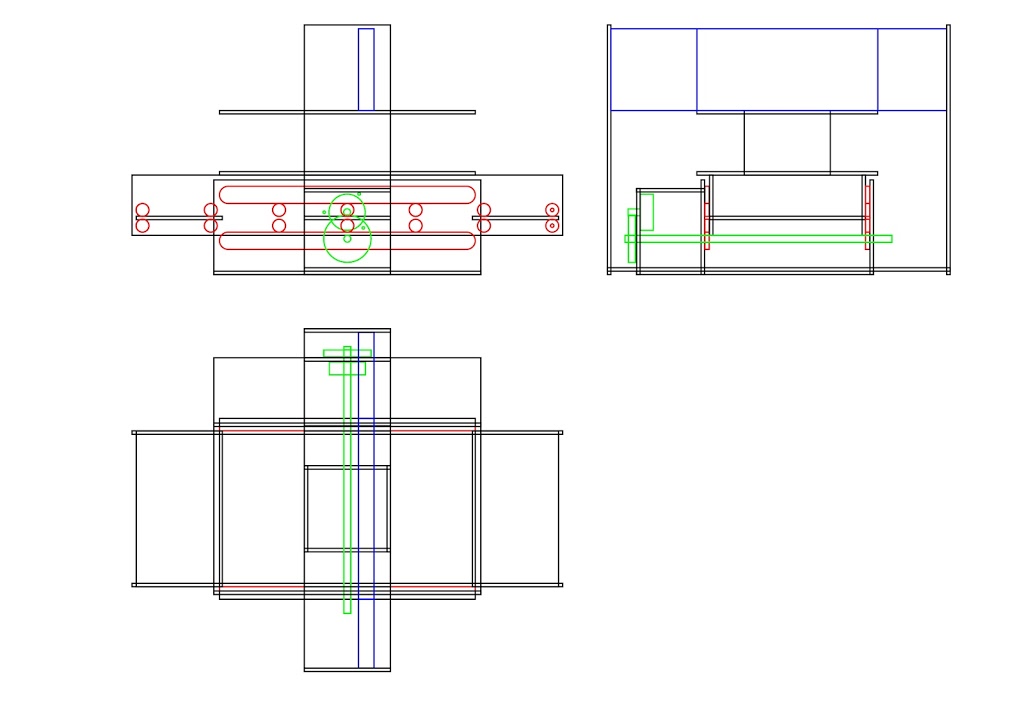

As it turns out the majority of the problems were related to the cable run in the top beam of the machine. Rather than having a proper cable track it was just a piece of ribbon cable with a piece of tape measure acting to keep the shape. The head of the machine(moving bit) and frame mount for the cable were VERY close with all the PCB and ribbon cable sockets, keeps snagging on the exposed solder and splitting the cable. This caused shorts and intermittent signal and completely messed the running of the machine.

You can see the green PCB above. As you can see from the patchy wiring on the head this has been worked on before. We have also added the green and red LEDs on a previous rebuild to help with problem identification. (red is pen up, green pen down, no light snapped wires!).

Rather than re-build it as before I decided to take the wiring external. Not ideal on most machines but frankly I have got board of replacing the same parts every couple of months.

Although there was a ribbon cable in there originally it was only wired in to two cables that activated the solenoid in the head. Moving this wiring elsewhere (with better quality wire, the stuff in there you can snap with 2 fingers) is nice and simple, the only problem is letting the head move without damaging the wire.

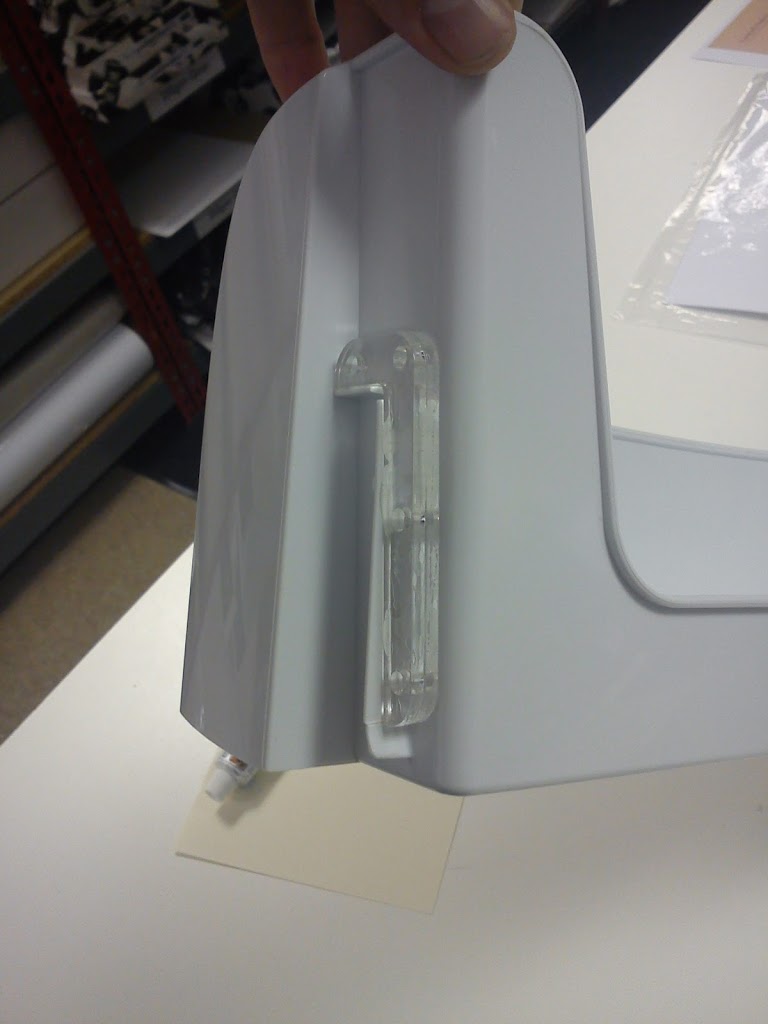

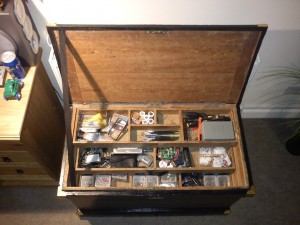

A quick trawl through the parts bin threw up an old telephone with a nice springy handset cable. After laser cutting a piece of ply…

…and a covering of black vinyl the centre cable “pylon” was sorted. The slot in the middle is a cable run.

I scavenged the cable sockets from the handset and base of the phone and wired them in to the machine at the top of the pylon and on the head. It now has a cable that can be unplugged and you never know, that may prove useful!

Everything bolted back together and it runs really well, although anything above 150mm/s makes the cable wobble about in a slightly worrying manner. The machine has now been commandeered by my wife for her business and should provide quite a bit of service before we have another problem.